Microwave solid flow switch/Material flow meter/Material flow switch

Microwave solid flow switchCAS100MThe measurement process is based on the physical principle of Doppler effect, so the sensor emits a microwave field. If the solid material moves through this wave field, the microwave will be reflected and received again by the sensor, and converted into a switching process.CAS100MMaterial flow that can be installed inside pipelines, on conveyor belts, on drop barriers, bucket elevators, chutes, wind conveyors, vibration troughs, or similar conveying facilities/Detection of no material flow. This device can detect flow problems during the transportation or feeding process of powder, debris, small spherical, granular materials in advance. This helps to avoid various serious problems caused by pipeline blockage, material loss, or other technical issues in the system.

Technical advantages:

● Reliable microwave measurement principle;

● Applicable to all materials;

● Adjustable sensitivity, damping, and hysteresis;

● Monitoring during the transportation of solid materials;

● Compact structure, easy to install;

● Process connections are made through flanges, threads, or other means.

Working principle

CAS100MMicrowave material flow detector is a solid material flow detector designed using the Doppler principle. The Doppler principle refers to the change in wavelength of radiation emitted by an object due to the relative motion between the wave source and the observer. In front of the moving wave source, the wave is compressed, the wavelength becomes shorter, and the frequency becomes higher; When the motion is behind the wave source, it will produce the opposite effect. The wavelength becomes longer and the frequency becomes lower. The higher the speed of the wave source, the greater the effect it produces. Based on the degree of microwave displacement, the velocity of the wave source moving in the observation direction can be calculated. In short, if the position of the object touched by the microwave is fixed, then the frequency of the reflected wave and the frequency of the emitted wave should be equal. If an object moves in the direction of emission, the reflected wave will be compressed, which means the frequency of the reflected wave will increase; On the contrary, the frequency of the reflected wave will decrease accordingly.

technical data

Housing material stainless steel

Sensor surface Teflon (optional ceramic)

protection grade IP65

ambient temperature -20°Cto +70°C

process temperature -20°Cto +90°C

Process pressure 2bar(Optional)25 bar)

power supply 18~36V DC

current consumption exist24 V DCApproximately80 mA

Transmission power <20 dBm

Output (switching) Relay output (switching contacts, no potential)

Switching Voltage 110V DC / 125 V AC

Switching Current 1A,110V; 0,5 A,125 V AC

switching power 30W / 35 VA

Electrical connection threaded

Adjustable parameters Sensitivity, signal damping, hysteresis

parameter Through potentiometers and switches

Explosion proof rating (optional) Applicable to regional types20And type1The EU Explosion proof Certification

indicator LEDGreen (work)

LEDRed (switching)

LEDYellow (flow indicator)

Application areas:

Animal feed industry, building materials industry, ceramic products, chemical industry, cleaning agents, food industry, glass production, metal production, pharmaceuticals, pigment production, power plants, recycling industry, synthetic materials, textile production, fertilizers, sewage treatment, mining, etc...

Application scope:

● Pneumatic chute cement flow detection;

● Monitor the transportation of raw material preheaters in cement plants;

● Monitor the flow of free fall feed;

● Secondary fuel flow detection of gas rising pipeline;

● Monitor the feeding situation of the spiral feeder in the gypsum plant;

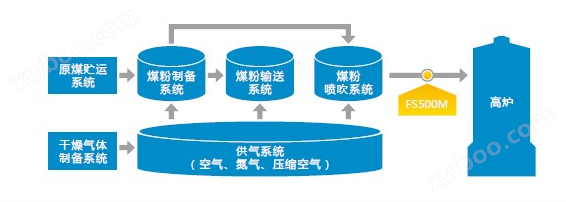

● Measurement of coal powder flow in blast furnace;

● Pneumatic conveying control of metal steel ball conveying;

● Free fall sugar beet pulp dust flow monitoring, etc.

Application Description

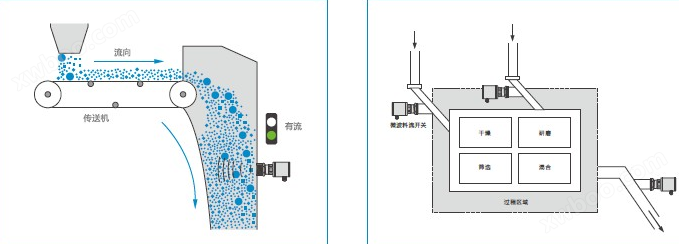

Application of pneumatic conveying Application of Material Flow Detection on Conveyors

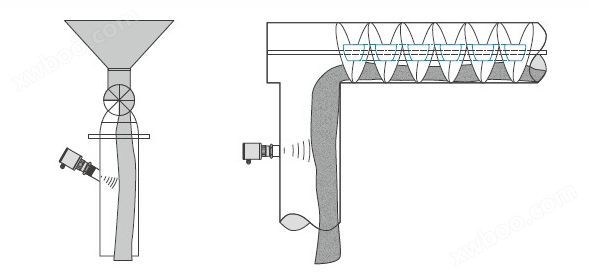

Application of chute blockage Process monitoring application

Application of detecting process pipeline blockage

Application of installation in conveying coal injection process of blast furnace

On site application of microwave solid flow switch: